Rubber Keypads

A rubber keypad is a type of switch that operates using compression-moulded silicone rubber actuators and conductive pills. Rubber keypads are extensively used in both commercial and industrial applications.

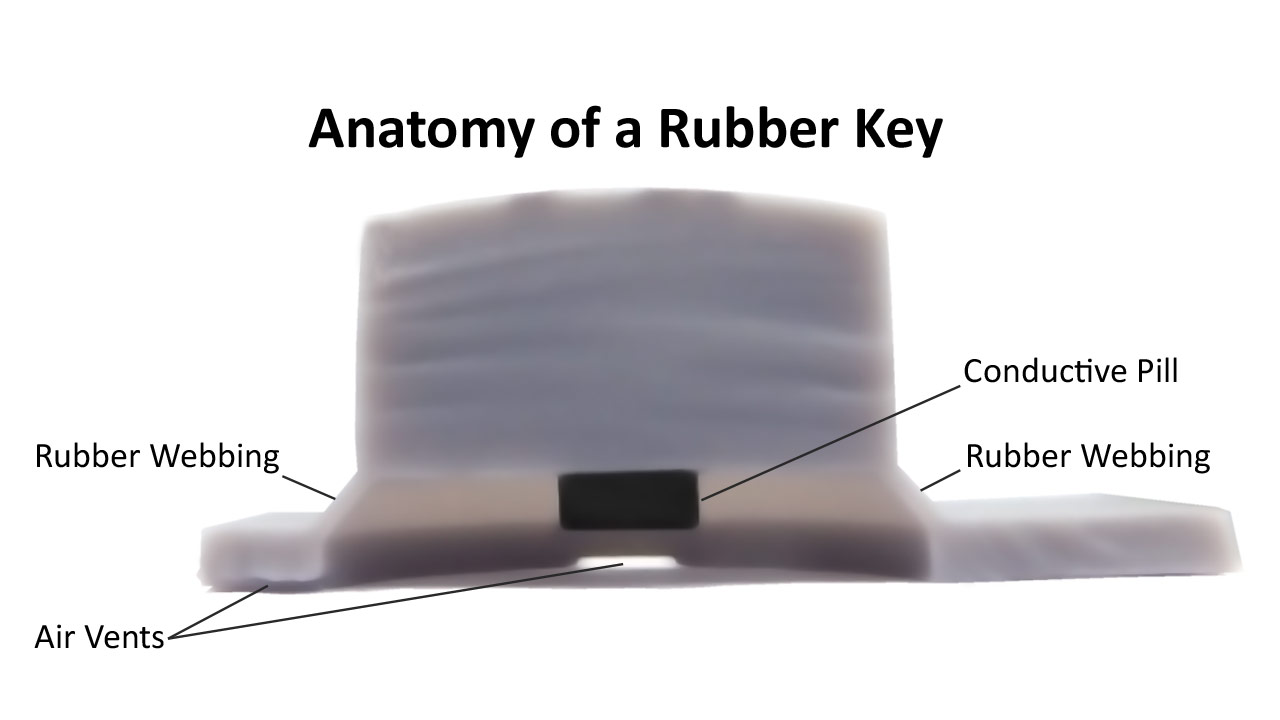

A single key consists of angled webbing around a switch center, with a conductive carbon or gold pill on the underside to act as a shorting pad. This key is placed on a base circuit, with the shorting pad directly over the switch contacts. When the key is depressed, the webbing deforms, producing a tactile response. The conductive pill shorts the switch contacts, closing the switch. When the key is released, the webbing causes the key to spring back into its neutral position with positive feedback, and the switch is then open again.

Rubber keypads are very versatile. The tactile response and key travel can be adjusted by changing the webbing design or by using different silicone base material. Alternatively, the tactile feedback can be further enhanced by using the rubber key to depress a metal dome. The aesthetics are also very customisable, as switch keys can be made in a wide variety of unusual shapes and colours.

Features and Benefits of Rubber Keypads

- Sealed Construction

- Rather than using gaskets, rubber keypads can be moulded in single-piece or wraparound designs to prevent ingress of liquids, dust or gases.

- Durable and Robust even in harsh conditions

- Silicone rubber keypads are resistant to moisture, chemicals, aging and extreme temperatures. Hence, they are reliable even in harsh environments.

- Highly Customisable

- The keys can be manufactured in almost any size and shape. Multiple colours are also possible by using flow moulding. Keys can also be printed with custom graphics.

- Backlighting Options

- A wide variety of backlighting options are possible. The entire switch can be lit up, or only certain portions of the text can also be lit up.

- Tactile Feedback

- The key travel and actuation force can be customised by using different webbing designs or silicone base materials.

- Low Unit Cost

- Rubber keypads require high initial tooling cost for the moulds, but the material costs are low. This makes rubber keypads an attractive option for high volume applications.